- Check Operational Configuration of all the valves and ensure all of them are in the nominal configuration (if not, contact the expert(s) before starting the cooldown)

- Check the LCW supply and ensure there is no issues with LCW parameters.

- Check all the coldhead compressors' screens and ensure there are no "ALARMS" on their display panels. Also, check the two gauges and ensure both gauges show ~200 psig (these are inlet, outlet pressure readings in/out the coldheads).

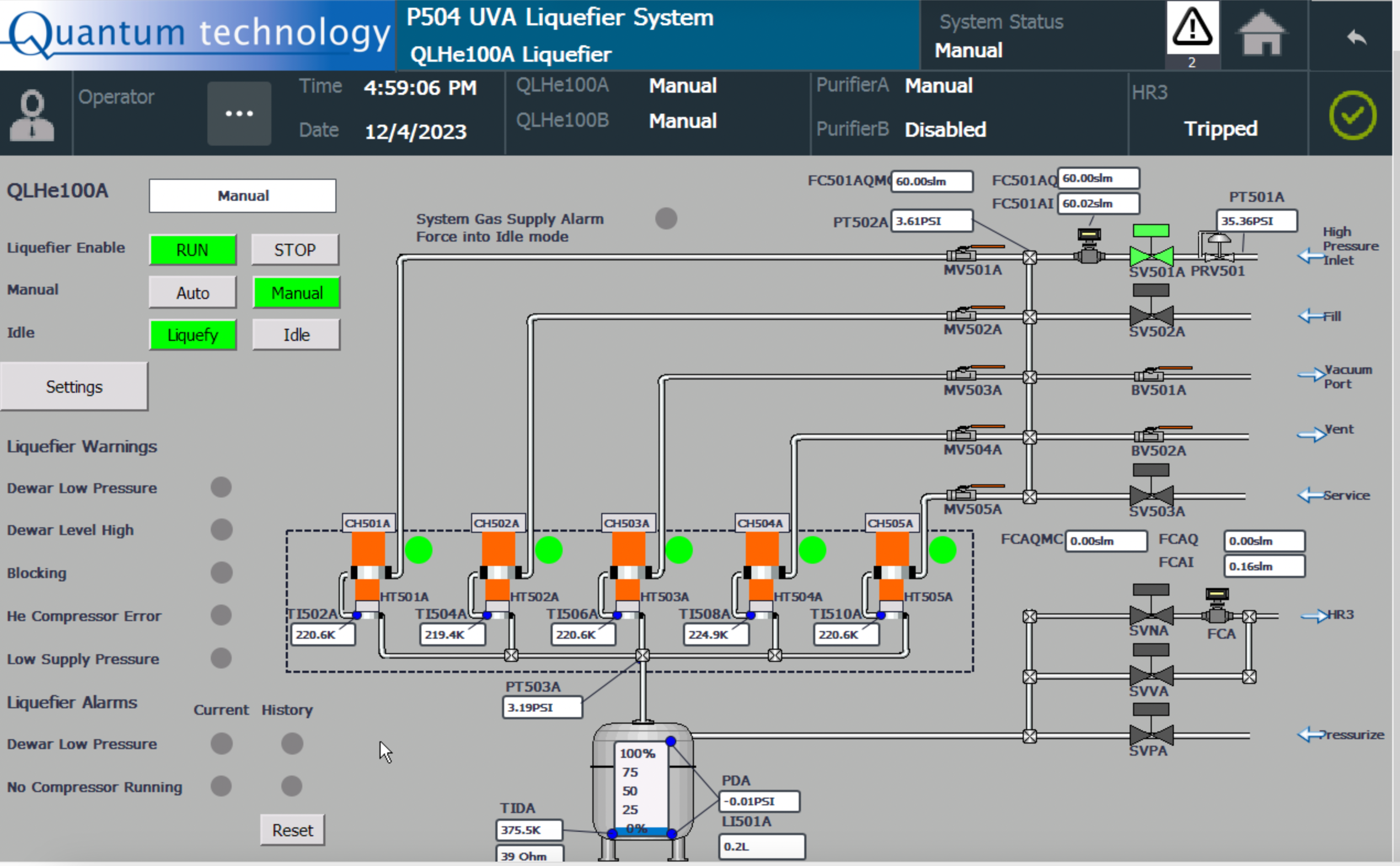

- Switch the LIquefier to Manual + Liquefy mode (Manual + Idle mode is also the same because Liquefy/Idle option has no effect when it is in the 'Manual' mode)

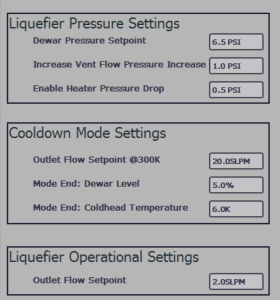

- Ensure the dewar pressure alarm threshold is around 0.2 psi (navigate to the Liquefier 'Settings' to check that).

- Set the inlet flow to 60slm: enter 60slm on FC501(A/B)Q (then press enter)

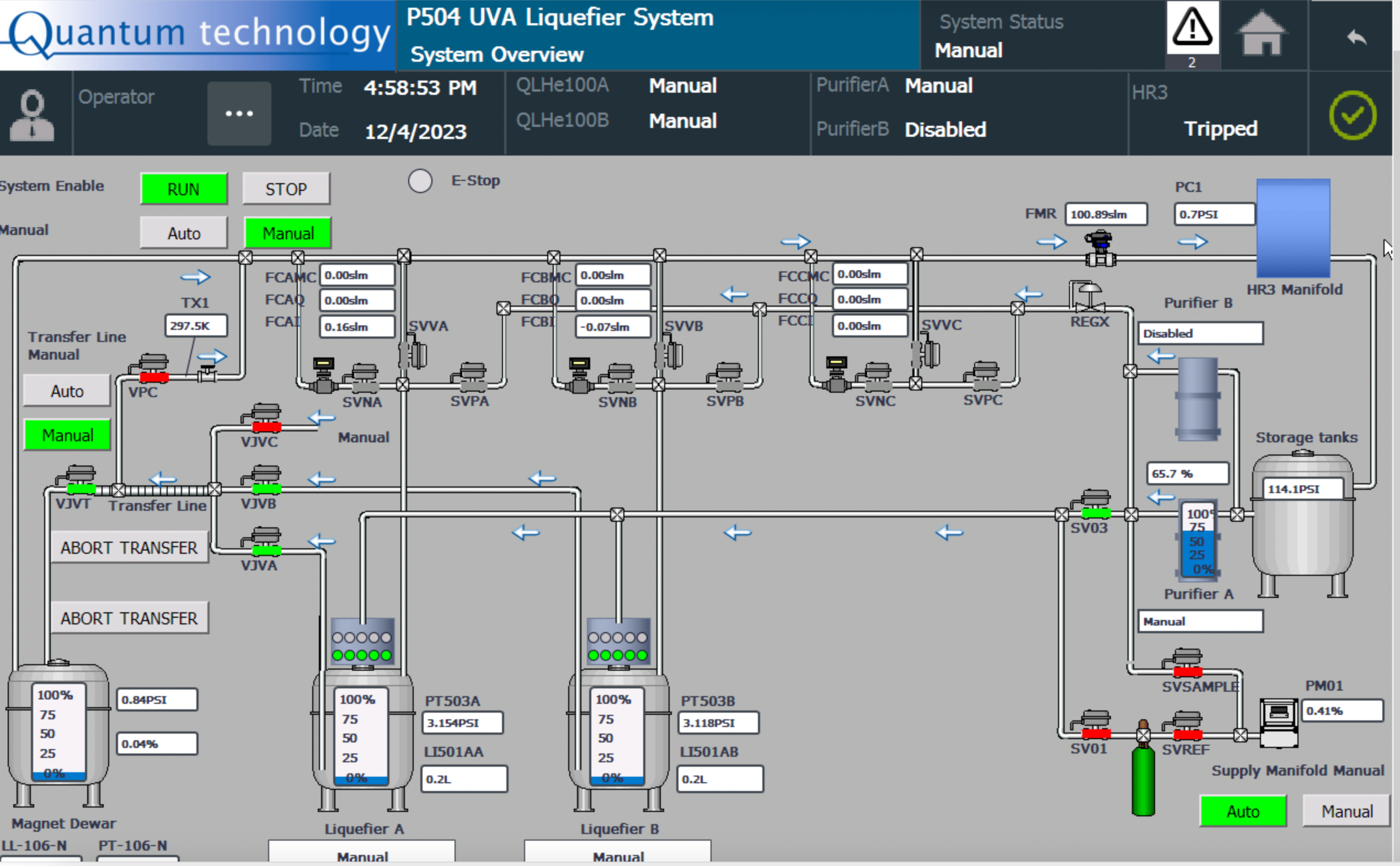

- Option 1: Set the outlet flow for the maximum flow by opening SVV(A/B) and the manual hand valve bypassing the SVN(A/B). You will observe the Dewar pressure will drop down to ~0.8psig and get stable.

Option 2: Open VJV(A/B), VJVT, open Magnet Bypass control valve to 70% have the flow through the magnet. You will observe the Dewar pressure will drop down starting from ~3.2psig.

- Skip this step if you are cooling down using the transfer stingers via magnet path

Option (1): Open the magic valve NV501A/B completely (~9 turns).

Option (2): Open SV503(A/B) and keep the magic valve (at ~1/2 a turn)

(see pictures on Supply Manifold for the Liquefiers) - Turn ON the cold heads manually on "Helium Compressors" screen

- Move the transfer stinger a few inches up (to avoid touching the bottom).

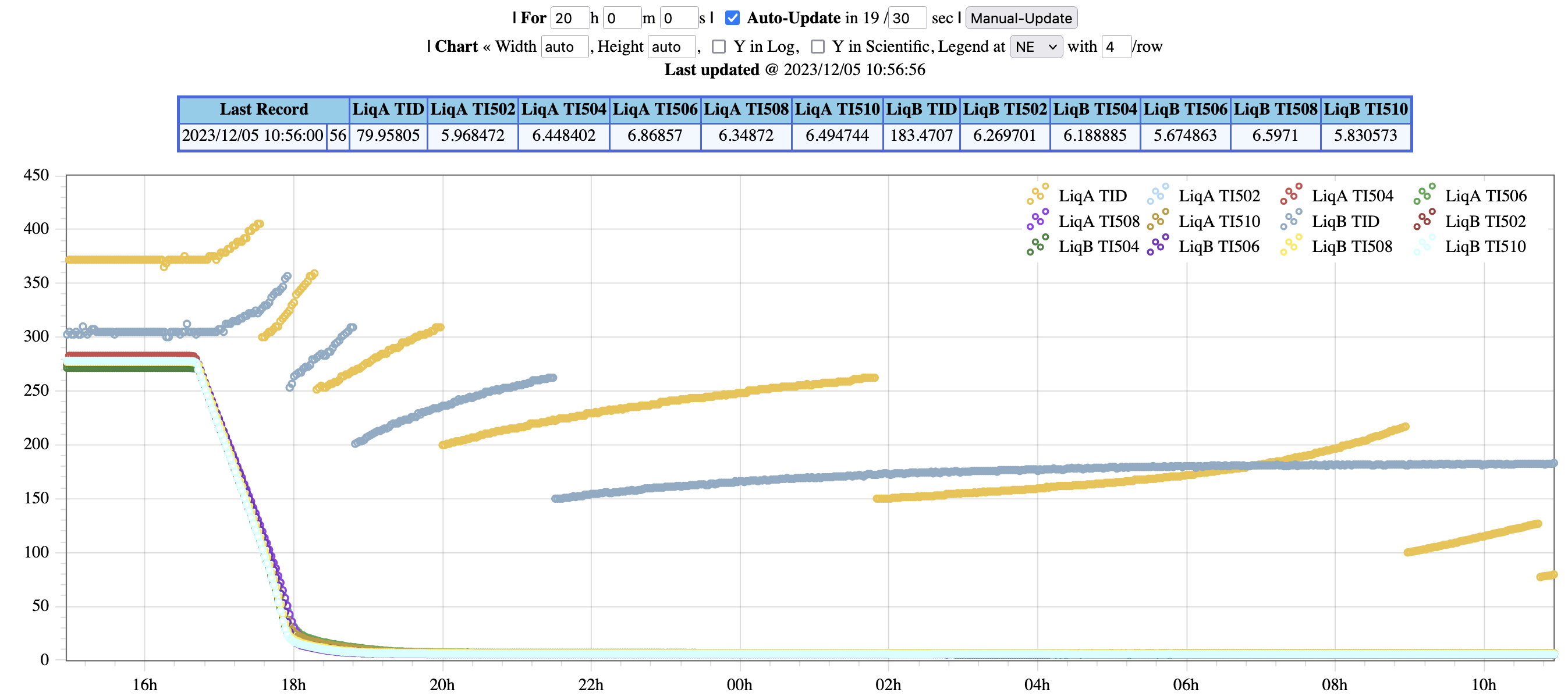

- It will take about 2 hrs and 30 mins for the cold head temperatures to reach ~5-6 Kelvin.

- Monitor A,B's TI502,TI504, TI506, TI508, TI510 and TIDA/B and you will observe all of them will have a slope towards 4 Kelvin (TIDA/B will be a bit slow compared to coldhead temperatures)

Note: This is for option (2) cooling via the magnet path. - Once cold head temperatures reach 4-5 Kelvin, and TIDA/B reach their lowest (below 10 Kelvin), then,

Option (1): Transition to have the outflow through SNVB (with the flow controller), and stop the flow through SVVA/B.

Close SVVA/B and open SVNA/B and set FCA/BQMC to 60slm.

Option (2): in the step (4): Close VJVA, Close VJVB, Close VJVT, and open VPC. Then, Open SVNA/B and set FCA/BQMC to 60slm. - Let/Ensure the Dewar pressures are above ~0.5 psig on both Dewars (this is to not let the Liquefiers go to the "ALARM" mode).

- Let it run in this configuration: in-flow 60slm, out-flow 60slm (via SVNA/B), cold-heads are running, mode: run+manual+liquefy

- You should expect ice/frost on Dewar neck during this phase, and you will have to use the heat gun to melt the frost.

- When you start seeing FCBI start going down while FC501B inlet is 60slm, then lower the value of FCBQMC step by step based on the FCBI.

- Once you bring FCBQMC down < 5slm, then check the Liquefier Settings screen to ensure the following values.

- Switch the Liquefier to Run + Auto + Liquefy mode

- Related to Step #5:

Option (1): Bring the magic valve position for optimizing for production ( open ~1/2 a turn)

Option (2): Close SV503 (A/B) and leave the magic valve open ~1/2 a turn (original position) - When the liquid starts accumulating, move the transfer stinger all the way down.

Overview

Content Tools