- Check Operational Configuration of all the valves and ensure all of them are in the nominal configuration (if not, contact the expert(s) before starting the cooldown)

- Check the LCW supply and ensure there is no issues with LCW parameters.

- Check all the coldhead compressors' screens and ensure there are no "ALARMS" on their display panels. Also, check the two gauges and ensure both gauges show ~200 psig (these are inlet, outlet pressure readings in/out the coldheads).

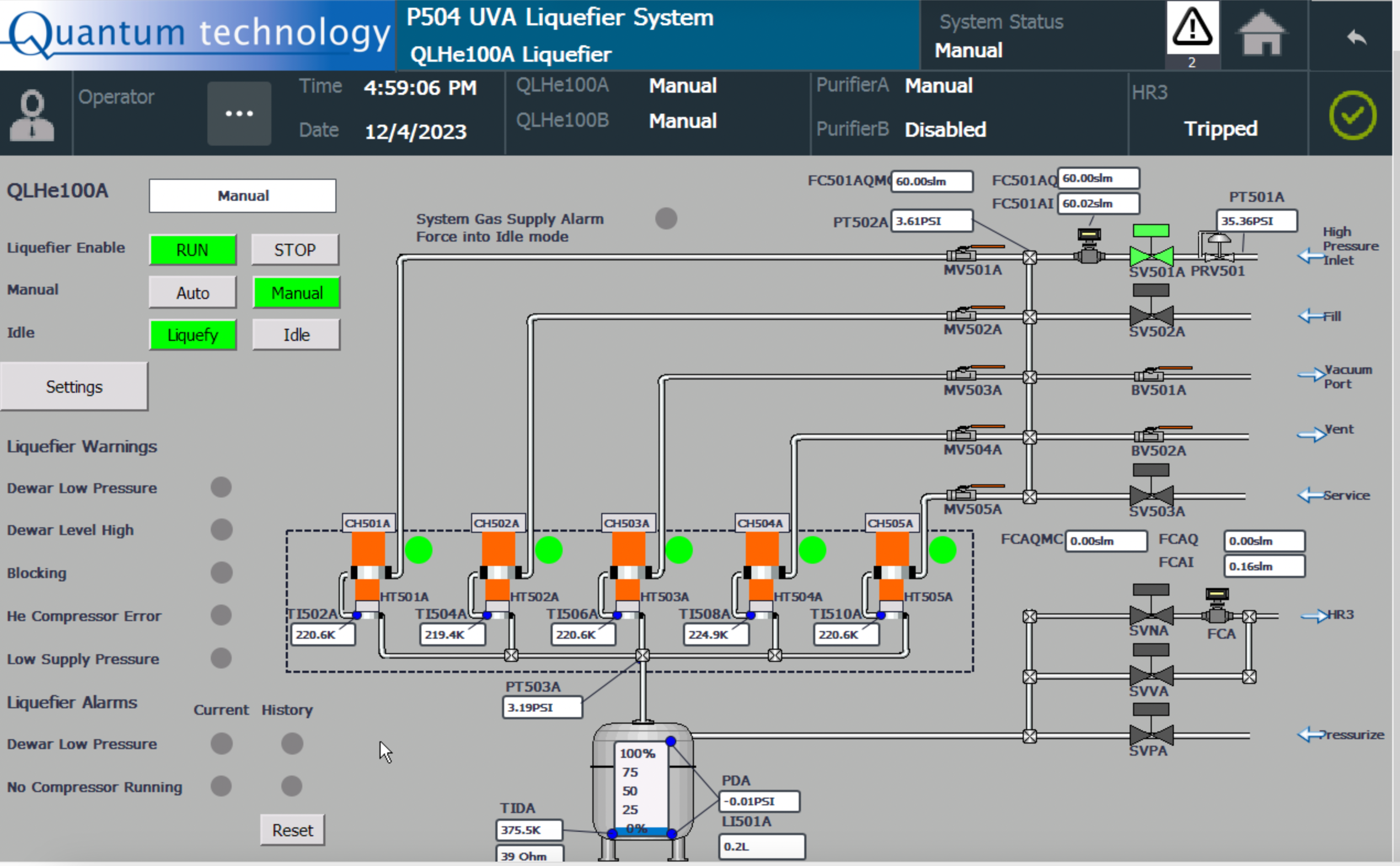

- Switch the LIquefier to Manual + Liquefy mode (Manual + Idle mode is also the same because Liquefy/Idle option has no effect when it is in the 'Manual' mode)

- Ensure the dewar pressure alarm threshold is around 0.2 psi (navigate to the Liquefier 'Settings' to check that).

- Set the inlet flow to 60slm: enter 60slm on FC501(A/B)Q (then press enter)

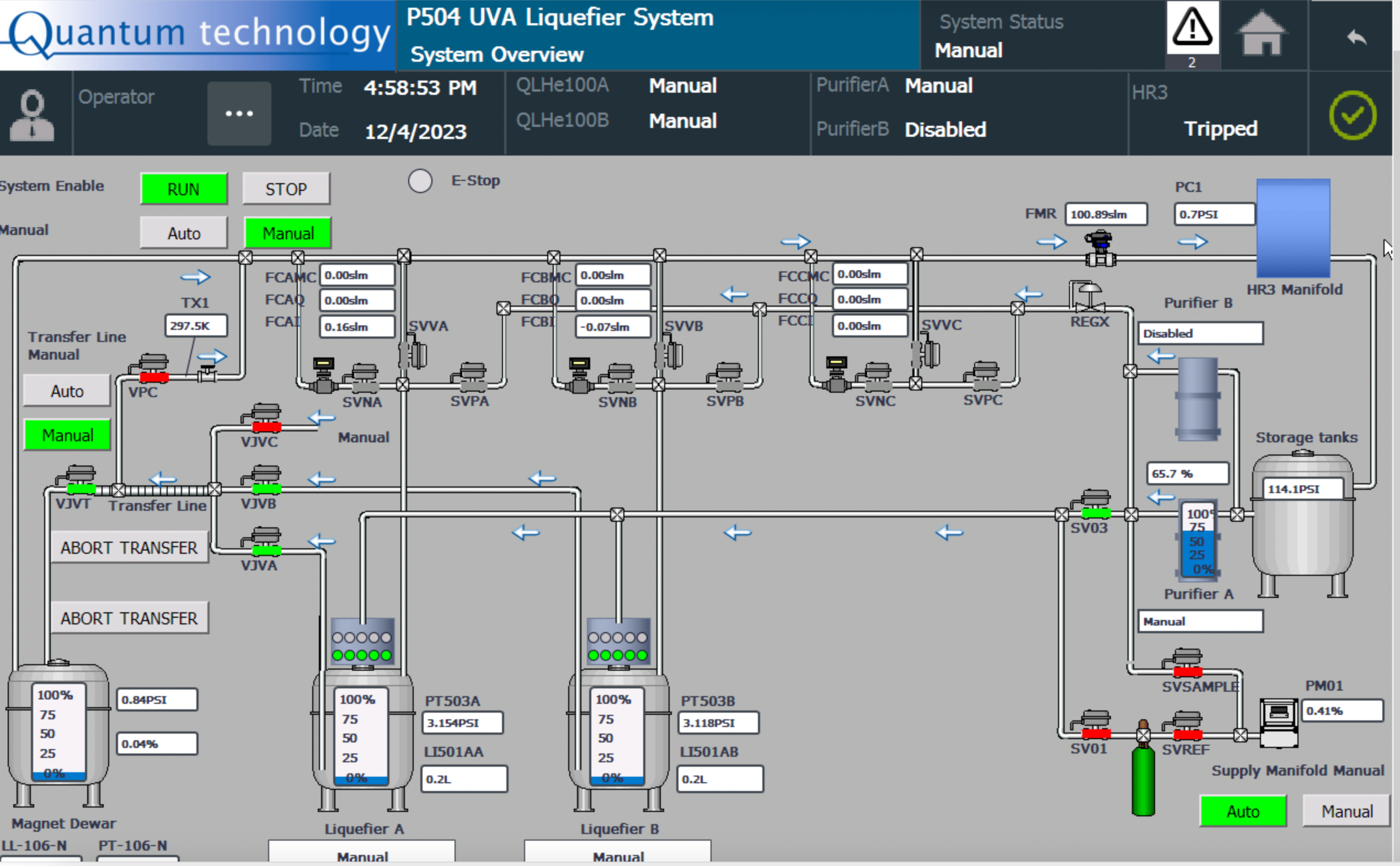

- Option 1: Set the outlet flow for the maximum flow by opening SVV(A/B) and the manual hand valve bypassing the SVN(A/B). You will observe the Dewar pressure will drop down to ~0.8psig and get stable.

Option 2: Open Open VJV(A/B), VJVT, open Magnet Bypass control valve to 70% have the flow through the magnet. You will observe the Dewar pressure will drop down starting from ~3.2psigto ~1.2 - 1.4 psig.

Skip this step if you are cooling down using the transfer stingers via magnet path

Option (1): Open the magic valve NV501A/B completely (~9 turns). Option (2): Open SV503(A/B) and keep the magic valve (at ~1/2 a turn)

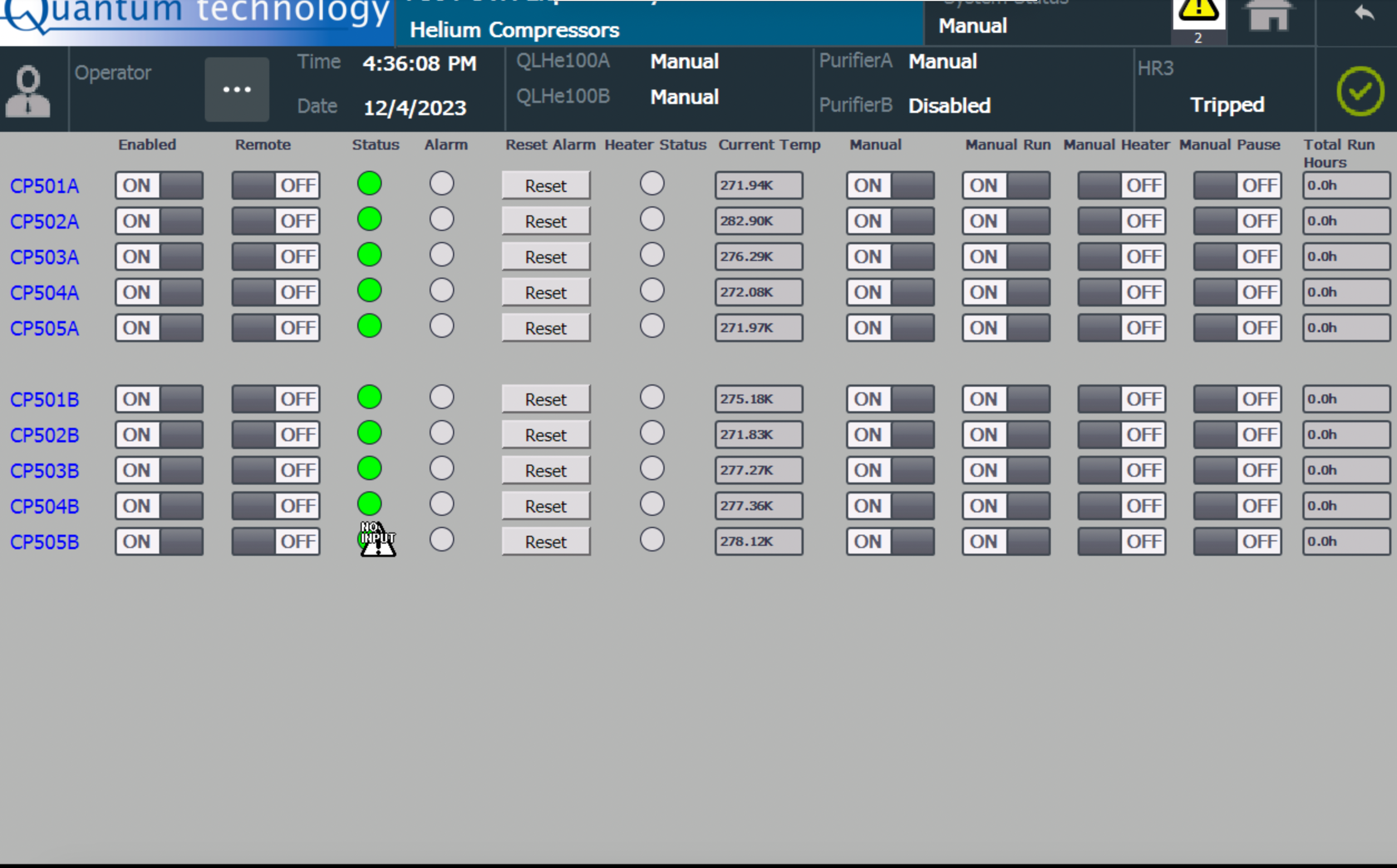

(see pictures on Supply Manifold for the Liquefiers) - Turn ON the cold heads manually on "Helium Compressors" screen (double click on "Manual Run" button on each coldhead compressor).

- Move the transfer stinger a few inches up (to avoid touching the bottom).

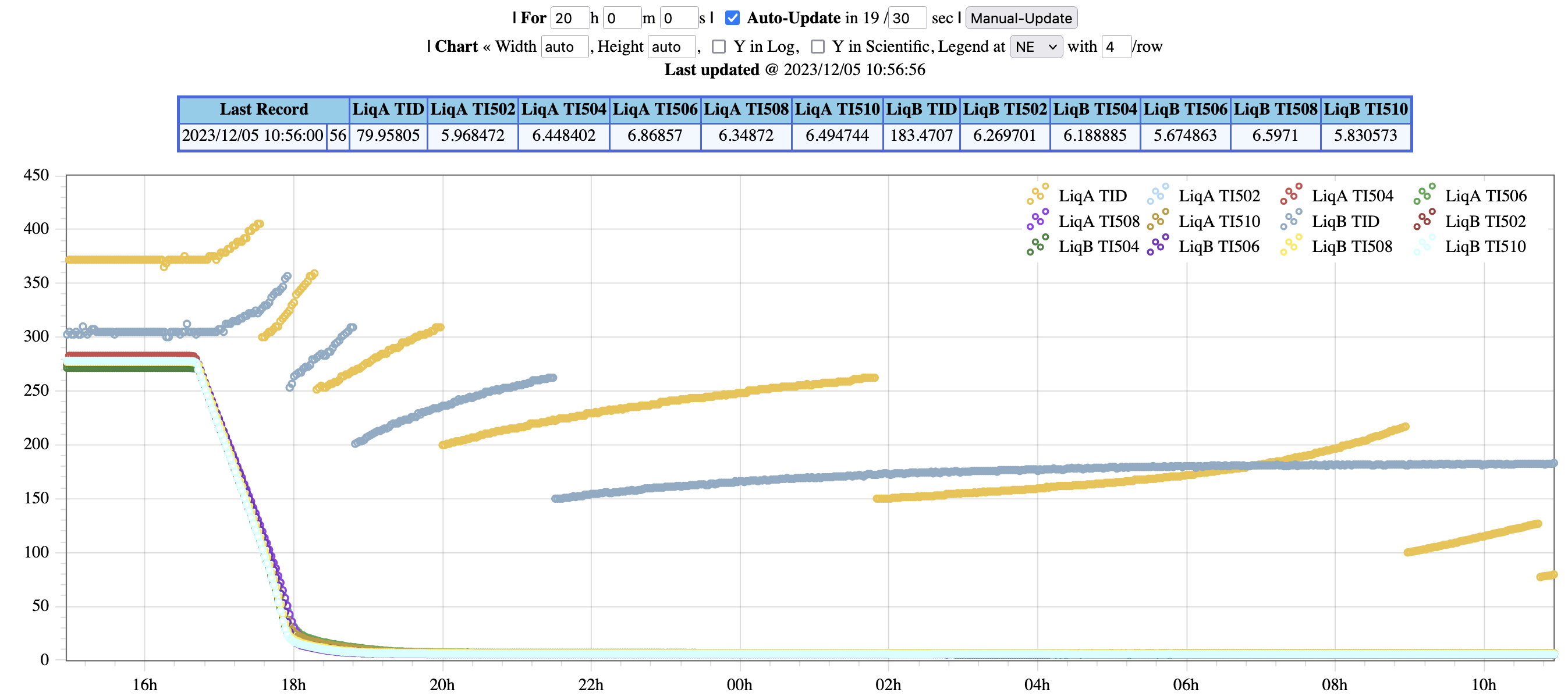

- It will take about 2 hrs and 30 mins for the cold head temperatures to reach ~5-6 Kelvin.

- Monitor A,B's TI502,TI504, TI506, TI508, TI510 and TIDA/B and you will observe all of them will have a slope towards 4 Kelvin (TIDA/B will be a bit slow slower in rate of cooling down compared to coldhead temperatures) Note: This is for option (2) cooling via the magnet path.

- Once cold head temperatures reach 4-5 Kelvin, and TIDA/B reach their lowest (below around 10 Kelvin), and also FMR flow started reducing, then,

Option (1): Transition to have : equivalent to ~324 Ohm), then you are ready to transition from "flowing through transfer line" to "flowing through regular outlet path of the Liquefier", i.e. the outflow through SNVB (with the flow controller), and stop the flow through SVVA/B.

Close SVVA/B and open SVNA/B and set FCA/BQMC to 60slm.

Option (2): in the step (4): Close set to 60slm. Note: you may have already noticed that the FMR flow started reducing which is a good indication of LHe production. Don't worry if you don't see that. Proceed to the next phase. - Close VJVA, Close VJVB, Close VJVT, and open VPC. Then, Open SVNA/B and set FCA/BQMC to 60slm. Ensure you inlet flow to the Liquefier is 60slm in this Manual mode.

- Let/Ensure the Dewar pressures are above ~0~6.5 psig on both Dewars (this is to not let the Liquefiers go to the "ALARM" mode).. If not, close SVNA/B temporarily to build the pressure to ~6.5psig and then open SVNA/B.

- Let the Liquefier Let it run in this configuration: in-flow 60slm, out-flow 60slm (via SVNA/B), cold-heads are running, mode: run+manual+liquefy.

- You should expect ice/frost on Dewar neck during this phase, and you will have to use the heat gun to melt the frost.

Optional: Open SV503A/B (Magic Valve Bypass) so then you can expect the neck will get cold faster. - When you start seeing either,

(1) the Dewar Pressure starts decreasing while having 60slm inflow and 60slm outlet flow, or

(2) FCBI start going down while FC501B inlet is 60slm,

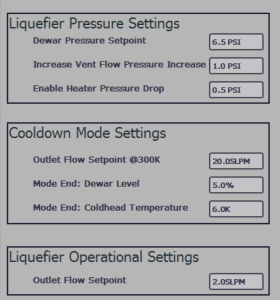

then lower the value of FCBQMC step by step based on the FCBI.FCA/BQMC to ~50slm (or lower) to stabilize the Dewar pressure around ~6.5 psig. If you realize that you will have to lower the FCA/BQMC more, then that's the indication that we will have to switch the Liquefier to "AUTO" mode. - Ensure Once you bring FCBQMC down < 5slm, then check the Liquefier Settings screen to ensure the following values.

. You can use "Outlet Flow Setpoint" to 10slm and then after a few hours change it back to 2slm. - Ensure, the Full system is in the RUN +AUTO mode. See the top-left corner. When you press this "AUTO" button, you may see that the "SVSAMPLE" valve can immediately becomes "OPEN". So you will first have to click "MANUAL" button at the bottom-right corner of the following screen (to enable that section of the valves to control manually) and then close "SVSAMPLE". Also check whether the "VPC" stays "OPEN" (again, you may have to click "MANUAL" button right below the "Transfer Line Manual" (middle-left)).

- Check the compressor screen and ensure "Remote" buttons are "ON" for each coldhead.

At this stage, the "Manual Run" is ON because you have been running the Liquefier on MANUAL+Liquefy mode. So, it is fine to leave the "Manual RUN" "ON" while you switch to "AUTO" in the next step (remember to turn them OFF on the following screen whenever the Liquefier is switched back to MANUAL mode). - Switch Switch the Liquefier to Run + Auto + Liquefy mode

- The liquefier will take about ~1 hr to start producing liquid from the time it was switched to the Run + Auto + Liquefy mode.

Note: The following plots show the nominal parameters under this configuration. Notice the Dewar level started increasing ~ 1hr since the time it was switched to the Run + Auto + Liquefy mode.

- Run in this configuration until you start seeing the increments on Dewar level. Then, change the Outlet Flow Setpoint to 2slm (nominal value) in the Liquefier's Settings screen. You will notice that FC(A/B)Q changed to 2slm.

Related to Step #5:

Option (1): Bring the magic valve position for optimizing for production ( open ~1/2 a turn)

Option (2): Close SV503 (A/B) and leave the magic valve open ~1/2 a turn (original position) - When the liquid starts accumulating, move the transfer stinger all the way down.

Page History

Overview

Content Tools