- Check the outside gHe pressure and make sure it is below 90 psi. If it's equal, near or above, then relief it's pressure down to ~80 psi.

- Check with Target Expert on Shift whether the REGX green hand valve is fixed to some pressure during the previous fill.

- Set the liquefier to "Manual" mode.

- Navigate to the liquefier page on the HMI screen.

- Open SVP(A/B).

- Navigate back to the "Overview Screen".

- Start pre-cool phase: Open VPC → Open VJV(A/B) → Monitor TX1, TX2, TX3

- Charts of TX1, TX2 & TX3: https://e906-gat1.fnal.gov/data-summary/e1039/target-par-preset/cool_down.php

- TX1 goes down below 100 K in 5 minutes. If not, there should be a problem.

- After ~8mins:

- Open the magnet-bypass valve (i.e. the black hand

- valve right next to the magnet flow controller)

- ,

- Open the Magnet Return flow, by changing the flow mode to "OPEN" on the "THCD_401_Main.vi" panel, and

- Open VJVT on the HMI screen.

- After ~1min: Close VPC and monitor magnet pressure.

*****************************************************************************************************************************************

** Note: If the REGX green hand valve is fixed (check with Target Expert on Shift), then do not change it: just proceed with step #10 *****

*****************************************************************************************************************************************

> If you need to change the pressure difference between the magnet and the Dewar then use the REGX all the time to maintain the pressure difference that you need (eg: ~4psi) - After a couple of minutes, you will observe that the magnet pressure drops down suddenly and stay around ~1.4-1.5 psi (this indicates that LHe is flowing to the magnet after the pre-cooling of the last part of the transfer line).

- Fill the magnet until the level shows ~44%.

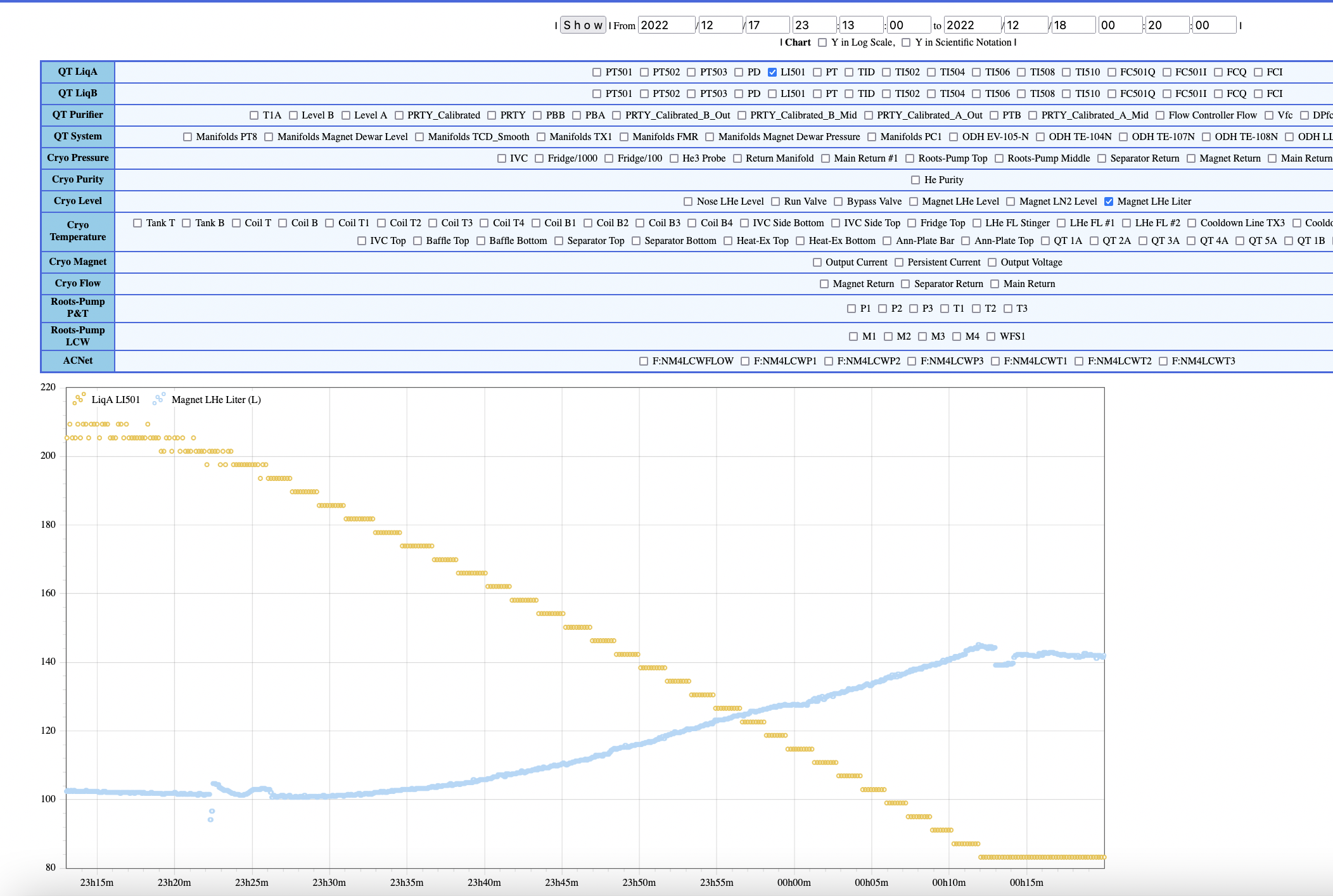

- Keep monitoring the liquid amount and the pressure at https://e906-gat1.fnal.gov/data-summary/e1039/target-par-preset/transfer.php.

- Any sudden change during the transfer indicates problem.

- Stop the fill. → Open VPC → Close VJVT →

- Open VPC

- Close VJVT

- Close VJV(A/B)

- Wait for 1-3 minutes until the magnet pressure (on the HMI screen) goes down to 1 psi.

- Close the → Close Magnet bypass hand valve.

- Change the mode of the Magnet Return flow from "OPEN" to "AUTO", and then click the "Automation" toggle switch.

- Make sure that you leave the VPC open, to capture all the boil-off from the transfer line until it is warm (check TX1). — We need not check TX1 but let VPC open, correct?

- Navigate to the liquefier page on the HMI screen and close SVP(A/B) → Switch the Liquefier to "Liquefy mode".

- Calculate the transfer efficiency of the transfer using https://e906-gat1.fnal.gov/data-summary/e1039/ (see the following screenshot as an example), and write an elog entry on UVA elog.

Page History

Overview

Content Tools